This study was performed to investigate the impact of an industrial thermal treatment process on the behavior of defect-free wood under compression loads. The authors contribute the rise in compression strength to the relative increase in lignin content and its condensation, which was confirmed using NIR spectroscopy (Windeisen et al. During compressive loading testing, a slight increase in the compression strength along the grain was reported for poplar, beech, and ash woods after the thermal modification procedure (Windeisen et al.

Consequently, the reexamination of the mechanical properties of thermally treated wood is desired when the material is purposed for construction applications. 1978 Bourgois and Guyonnet 1988 Yildiz and Gümüskaya 2007) and appear to be involved in the effect of thermal treatment on the general reduction of wood mechanical properties (Kubojima et al. 2003), creep dependency (Keith 1972), and the strain rate effects (Reid and Peng 1997 Vural and Ravichandran 2003).Ĭhanges and modifications to the wooden components were confirmed after the thermal treatment of wood from previous works (Kollmann and Fengel 1965 Dietrichs et al. 2013a), size effects (Schneeweiss 1963 Dill-Langer et al. Further publications examined the different angles of the grain (Reiterer and Stanzl-Tschegg 2001), and special aspects, such as the impact of temperature, moisture content (Hering et al. In reference to compressive loads, many studies have been conducted on elastic compression mechanisms (Bodig and Jayne 1982 Niemz 1993) and underlying fracture criteria (Daudeville 1999 Mackenzie-Helnwein et al. The numerical data of strength and stiffness of solid wood from several published works (Kollmann and Cote 1968 Dinwoodie 2000 Mackerle 2005) has been reported. The load-bearing safety of structural units is usually acquired on the basis of experimental investigations with subsequent finite element (FE) simulations (Gaff et al. Timber engineering deals with the evaluation of the load-bearing capacity of structural members in areas connected with mechanical connectors, openings, and notches.

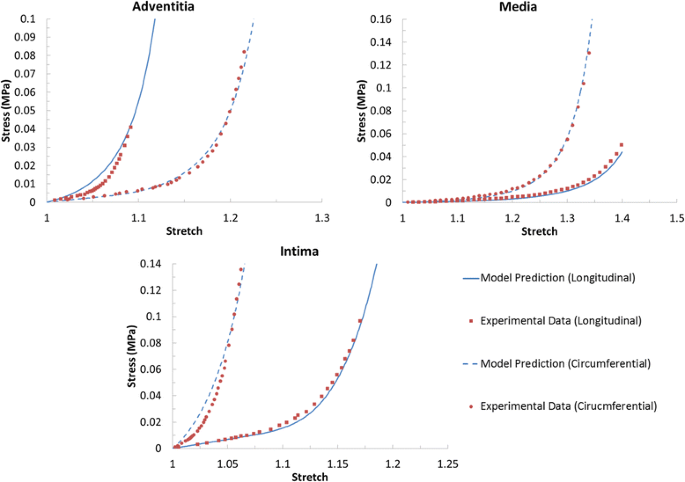

The important negative aspect of thermal modification is the loss in mass and strength, and the alteration of stiffness, which limit the potential use of thermally treated wood in structural applications. Keywords: Thermally-treated beech wood Mechanical properties Numerical simulationĬontact information: a: Department of Wood Sciences and Technology, Biotechnical Faculty, University of Ljubljana, Jamnikarjeva 101, SI-1000 Ljubljana, Slovenia b: The College of Industrial Engineering, Mariborska Cesta 2, SI-3000 Celje, Slovenia c: Prometheus, Boštjan Zafošnik s.p., Tacenska Cesta 125E, 1000 Ljubljana, Slovenia *Corresponding author: treatment is a promising, environmentally friendly method for the protection of wood that reduces its hygroscopicity and consequently improves its dimensional stability and durability, both of which are needed for outdoor applications (Bourgois and Guyonnet 1988 Tjeerdsma et al. Gorazd Fajdiga, a Boštjan Zafošnik, b,c Bojan Gospodarič, a and Aleš Straže a,* Based on the comparison of experimental and numerical results, it is possible to use the hyperelastic constitutive law to reasonably model the force and displacement obtained in the compression test samples.Ĭompression Test of Thermally-Treated Beech Wood: Experimental and Numerical Analysis After the thermal treatment, the strength of beech wood increased in the direction parallel to the grain and decreased in the direction transverse to the grain. It was confirmed that, after thermal modification, the wood’s density decreased and the stiffness in both tested directions increased. Afterwards, the test was modelled using the finite element method. In a normal climate, samples with the dimensions of 20 x 20 x 20 mm were exposed to static compressive loads parallel and transverse to the grain.

11(1), 223-234.Įxperimental and numerical analysis of a compression test carried out on samples of as-received and thermally-treated beech ( Fagus sylvatica L.) wood is presented. "Compression test of thermally-treated beech wood: Experimental and numerical analysis," BioRes. Fajdiga, G., Zafošnik, B., Gospodarič, B., and Straže, A.

0 kommentar(er)

0 kommentar(er)